Not every facility has the same needs. Which exit sign styles make sense for your facility type? This buyer’s guide helps you choose the right battery-backup exit signs for 2026 by building type—schools, warehouses, hospitals, cold storage, wet/outdoor, and hazardous industrial sites. We’ll explain how emergency backup works, which certifications to look for, and how to stay inspection-ready under UL 924 and NFPA 101. For fundamentals on placement, arrows, and testing, see Exit Signs 101.

- Match the environment rating (standard indoor vs damp/wet vs NEMA 4X/IP66 vs cold-rated vs hazardous-location listed).

- Choose the form factor (exit-only vs exit/emergency combo vs remote-capable for extra heads).

- Reduce maintenance with self-testing diagnostics and a battery replacement plan.

Quick Picks

Schools

- Pick: Self-testing LED exit sign or combo; use a vandal-resistant model in high-abuse areas.

- Why: High foot traffic and potential rough use; self-diagnostics cut down on manual maintenance checks.

- Require: UL 924 compliance (90-min runtime) and NFPA 101; dual-voltage input (120/277 VAC).

Warehouses & Wet

- Pick: High-output exit/emergency combo; use NEMA 4X/IP66 units in wet or dusty areas.

- Why: Large spaces need broad light coverage; units must withstand dust, water, and vibration.

- Require: UL 924 listed; Damp/Wet Location rating as needed; dual-voltage (120/277 VAC).

Hospitals & HazLoc

- Hospitals: Architectural edge-lit LED exit signs with self-diagnostics; quiet, low-profile design for patient areas.

- Hazardous: Explosion-proof exit sign rated for Class I Div 2 (or Div 1 if required).

- Require: UL 924 listing; adhere to site policy/AHJ testing expectations; UL 844 (hazardous location) rating as needed.

Battery-Backup Basics (How They Work)

Battery-backup exit signs operate on building AC power during normal conditions and include an internal battery pack that automatically takes over when the power goes out. To meet safety codes like UL 924 and NFPA 101, they must provide at least 90 minutes of illumination during an outage. Modern units use efficient LEDs, intelligent chargers, and often self-diagnostic controls to minimize maintenance needs.

Key components

- LED legend: Red or green EXIT lettering, typically 6-inch high for visibility.

- Battery pack: Often Ni-Cd (reliable, rugged); some use NiMH or LiFePO4 for longer life and lower maintenance.

- Charger & controller: Manages battery charging, provides brownout protection and low-voltage disconnect, and sometimes runs self-test diagnostics.

- Test interface: Usually a push-to-test button and status LED; newer models log monthly and annual test results automatically.

Exit-only vs. combo vs. remote-capable

- Exit-only: Best when you only need the illuminated EXIT legend.

- Exit/emergency combo: Best when you also need area illumination near the sign (doors, aisles, stairwells).

- Remote-capable: Best when one unit’s battery can also power additional remote emergency heads.

Battery chemistries (quick view)

- Ni-Cd: Reliable in a wide temp range; typical lifespan ~3–5 years.

- LiFePO4: Longer service life (often 8–10 years) in typical indoor conditions; may need a heater in very cold environments.

- Lead-calcium/NiMH (select units): Used in specialty high-capacity units (e.g., running remote heads); heavier and less common.

What Features to Look For (Battery-Powered Exit Signs)

If you’re comparing models, these are the specs that most often determine whether a unit holds up in real facilities—and stays inspection-ready.

- Certification: UL 924 listing (and UL 844 for hazardous locations where required).

- 90-minute runtime: Confirm performance at the coldest ambient you expect (especially in freezers and unconditioned spaces).

- Self-testing diagnostics: Reduces lift time and helps catch failures before inspections.

- Environment rating: Damp/Wet Location as needed; step up to NEMA 4X/IP66 for wash-down, outdoor, or corrosion-prone areas.

- Durability: Steel/die-cast housings and/or wire guards in high-impact zones.

- Wiring flexibility: Dual-voltage (120/277 VAC) and universal mounting options (wall/ceiling/end).

- Serviceability: Easy access to battery packs and readily available replacement parts.

- Directional clarity: Field-selectable chevrons and a consistent red/green color standard throughout your facility.

Compliance Snapshot: UL 924, NFPA 101, OSHA

- UL 924: Sets performance standards for emergency lighting and exit signs (e.g., 90-min minimum battery runtime, visibility, recharge time, diagnostics).

- NFPA 101 (Life Safety Code): Requires exit signs to be visible along egress routes and mandates regular testing: monthly 30-second functionality tests and an annual 90-minute full-duration test.

- OSHA: Exit routes must be marked with illuminated signs at all times, and signage must remain visible (not obstructed) even during outages.

- Special jurisdictions: Certain cities (e.g., NYC, Chicago) may require special exit sign specifications—larger letters, unique legends like “STAIR,” or all-metal construction. Always check local code requirements.

Best Picks by Building Type

Schools

What to buy: Choose a standard LED exit sign or an exit/emergency combo unit with self-diagnostic testing to reduce manual checks. In areas prone to rough use (like gyms or busy halls), opt for a vandal-resistant steel housing or a protective mount/guard.

- Require: UL 924 compliant (90-min runtime) and meets NFPA 101; dual-voltage (120/277 VAC) wiring.

- Nice-to-have: Universal mounting (ceiling, end, or wall), field-selectable directional chevrons, and optional wire guard covers.

- Common mistakes: Using fragile plastic units in high-impact areas; not planning arrow directions; failing to keep testing log entries.

Warehouses

What to buy: Install high-output exit sign/emergency light combo units to cover wide doors and aisles. Use NEMA 4X/IP66 rated models if the area is dusty, gets washed down, or is exposed to weather. Add metal wire guards in forklift lanes for protection.

- Require: UL 924 listed; Damp or Wet Location rating as appropriate; supports 120/277 VAC.

- Nice-to-have: Remote-capable battery (to power extra remote lamp heads if needed); heavy-duty housings for durability.

- Common mistakes: Undersized lamp heads for high ceilings; not sealing enclosures in dusty areas; signs blocked from view by tall racks.

Hospitals

What to buy: Use architectural edge-lit LED exit signs with self-testing features in corridors/public areas, plus compact combos in stairwells or spaces not backed by a generator. Select quiet, low-profile designs that won’t disturb patients or aesthetics.

- Require: UL 924 listing; follow NFPA 101 and site policy/AHJ expectations; at least Damp Location rated.

- Nice-to-have: Recessed kits, field-selectable red/green letters, LiFePO4 batteries for less frequent replacement.

- Common mistakes: Mixing red/green in one facility; placing signs where complex layouts obscure them; poor recordkeeping.

Cold Storage

What to buy: Install cold-weather rated exit signs or combos with internal battery heaters (rated to –4°F, –20°F, or –40°F as needed). Prefer NEMA 4X/IP66 sealed enclosures; use adjustable LED heads to light long freezer aisles.

- Require: UL 924 performance at the lowest ambient temperature; sealed/insulated enclosure; verify minimum operating temp on the spec sheet.

- Nice-to-have: Remote battery located outside the freezer (to power heads inside); sealed conduit glands at penetrations.

- Common mistakes: Using standard signs in freezing conditions; not testing at actual cold temps; unsealed openings causing frost/condensation.

Wet Locations (Outdoors, Wash-Down)

What to buy: Choose NEMA 4X/IP66 waterproof LED exit signs/combos with corrosion-resistant parts (stainless hardware, UV-stable lenses). In parking garages, loading docks, outdoor canopies, or food prep areas, these units keep out rain, spray, and dirt.

- Require: UL 924 listed; Wet Location rated (gasketed) as needed; UV-resistant materials for sun exposure.

- Nice-to-have: NSF-certified for food facilities; multiple mounts (top/end/wall); tamper-resistant screws.

- Common mistakes: Using “Damp Location” units fully outdoors; no sealant on conduit entries; legends fading due to non-UV coatings.

Not sure whether you need Damp, Wet, or NEMA 4X/IP66? See Wet Location vs. Damp Location Exit Signs — NEMA/IP Rating Guide.

Hazardous Locations

What to buy: Only use exit signs explicitly certified for the classification (Class I/II, Div 1/2). These are typically explosion-proof fixtures with heavy cast housings, flame-arresting designs, and sealed electronics. In lower-risk Div 2 areas, a smaller haz-loc rated LED exit sign may suffice if it carries the correct Class/Division/Group markings.

- Require: UL 924 and UL 844; correct Class/Division/Group rating; NEMA 4X for outdoor/exposed installs.

- Nice-to-have: Self-diagnostics; external test button rated for haz-loc; ceiling/pendant mounts per hazardous wiring codes.

- Common mistakes: Installing a standard sign in a classified area; swapping parts that void ratings; leaving covers loose, compromising the seal.

Testing & Maintenance (Logs Included)

Required cadence

- Monthly: 30-second functional test (push-to-test or verify self-test) on each unit.

- Annually: Full 90-minute outage test; verify legibility end-to-end; log pass/fail and fixes.

- Always: Keep a written log with date, type, results, and corrective actions.

Exit sign battery replacement (quick guidance)

- Replace immediately if the unit fails the 90-minute test, won’t charge, or shows swelling/corrosion.

- Replace in batches by area to avoid scattered failures and simplify planning.

- Document it (battery date + unit ID/location) and re-test after replacement.

Pro tips

- Standardize on self-testing models to reduce lifts and after-hours tests.

- In freezers, perform the 90-minute test at actual cold ambient to validate the heater and battery.

- Use wire guards and robust anchors in gyms and warehouses to prevent damage.

Comparison Tables & Buying Checklist

Battery chemistry vs. environment

| Chemistry | Pros | Watch-outs | Great for |

|---|---|---|---|

| Ni-Cd | Tough, handles cold; proven 90-min runtime | Replace ~3–5 years | Schools, warehouses, wet/cold (with heater) |

| LiFePO4 | Long life, low maintenance, light | May need heater in deep cold | Hospitals, offices, general indoor |

| Lead-calcium / NiMH | High capacity (supports remote heads) | Heavy; niche | Large sites with many remote heads |

Housing & enclosure selection

| Housing | Strengths | Use cases |

|---|---|---|

| Thermoplastic | Low cost, light, fast install | Indoors (low-abuse; add guard if needed) |

| Steel/Die-cast | Durable, tamper-resistant | Schools, warehouses, public cores |

| NEMA 4X/IP66 | Sealed, corrosion-proof, washable | Wet/outdoor, food processing, cold storage |

| Explosion-proof (UL 844) | Flame-arresting design, safe in flammables | Any Class I/II Div 1/2 area |

Buyer’s checklist

- Certifications: UL 924 (and UL 844 for haz-loc); Damp/Wet or NEMA 4X if required.

- Runtime: ≥90 minutes on battery at the coldest ambient you expect.

- Diagnostics: Self-testing or clear fault indicators.

- Power: Dual-voltage input; remote-capable if driving extra heads.

- Mounting: Hardware for wall/ceiling/end; secure against vibration/abuse.

- Service: Accessible battery/electronics; readily available spares.

Checklists & Templates

Exit Sign Testing Log (CSV)

Columns: Location, Unit ID, Date, Test (Monthly/Annual), Result (Pass/Fail), Notes, Tech Initials.

Maintenance Schedule (CSV)

- Monthly 30-second test (automatic or manual)

- Annual 90-minute discharge test

- Battery age tracking and replacement planning

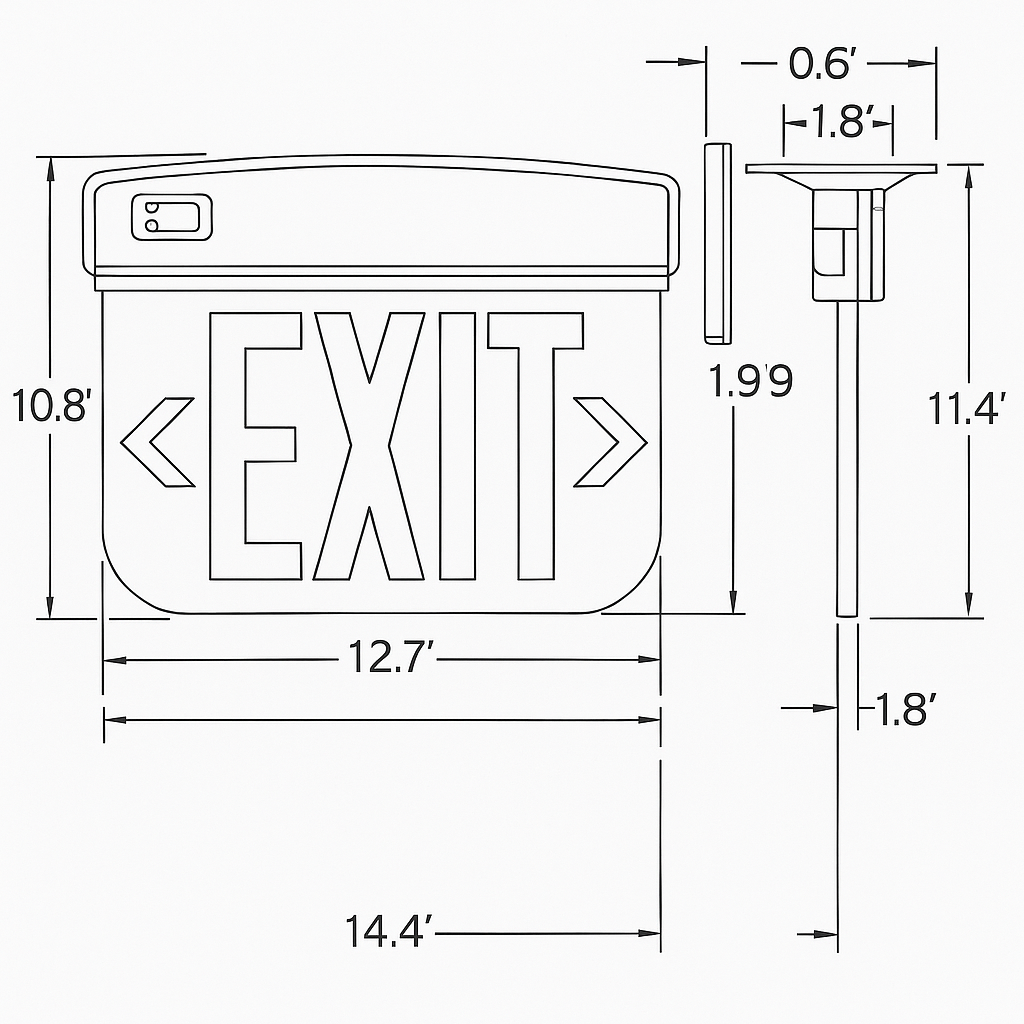

Visuals & Explainers

Frequently Asked Questions

How long do exit sign batteries last?

Most battery packs last ~3–5 years for Ni-Cd types, and up to 8–10 years for LiFePO4 in typical indoor conditions. Replace early if a unit fails a 90-minute test.

Do self-testing signs satisfy NFPA 101 testing?

Yes. Self-diagnostic signs perform the monthly and annual tests automatically. You still need a monthly visual check and a written record of results.

Exit sign battery replacement: do I have to replace the whole unit?

Not always. Many units allow battery pack replacement. Replace the battery if it won’t hold the full runtime, won’t charge, or shows damage. After replacement, record the date and re-test per your maintenance policy/AHJ.

What does “remote-capable” mean?

It means one unit’s battery can also power additional remote emergency heads. Ensure total wattage stays within capacity for a 90-minute runtime.

Red vs. green letters—does it matter?

Both are generally code-compliant unless your AHJ specifies one. Pick a single color and use it consistently throughout the building.

What’s the difference between Wet Location and NEMA 4X?

Wet Location is water exposure-ready; NEMA 4X is water- and dust-tight and corrosion-resistant—suited for harsher environments.

Can I use a standard sign in a freezer?

No. Freezers require cold-rated signs (often with internal heaters). Verify the model’s minimum operating temperature.

Tools & Calls-to-Action

Remote-Head Load Calculator

Enter head wattage and quantity to size battery capacity for a 90-minute runtime.

Spec Review

Share your environment (cold, wet, hazardous, etc.). We’ll suggest compliant models that match your constraints.

Talk to a Code Specialist

Get guidance on how UL 924, NFPA 101 tests, and AHJ expectations apply to your building.